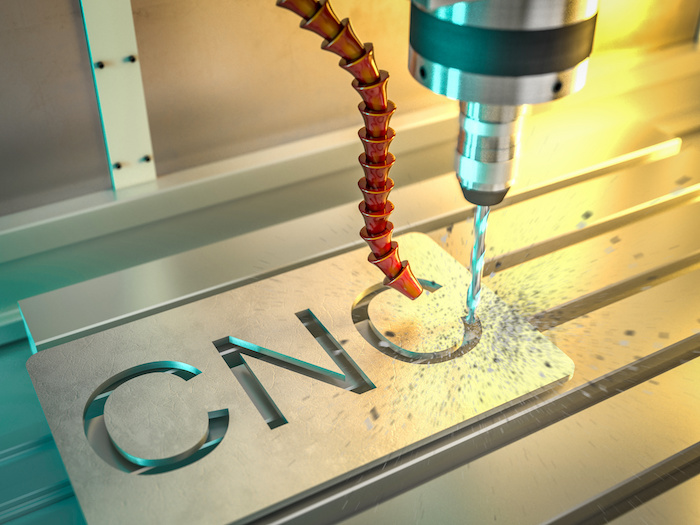

How to compare prices and quality for cnc milling services near me

Raise Your Manufacturing High Quality With Expert CNC Machining Services in Milling and Transforming

CNC machining solutions in milling and turning deal significant advantages for producing procedures. These processes assure precision and performance, vital for creating top quality parts. With innovative innovation and experienced machinists, services can achieve elaborate layouts and exceptional coatings. However, recognizing the subtleties of these solutions is important for maximizing their benefits. What factors should firms take into consideration when choosing the ideal CNC machining companion?

Recognizing CNC Machining and Its Advantages

Lots of manufacturing procedures exist, CNC machining stands out due to its accuracy and effectiveness. This sophisticated production technique uses computer-controlled machines to produce complex parts with minimal human treatment. By automating the machining process, it greatly minimizes the likelihood of human mistake, making sure consistent high quality across production runs

CNC machining supplies countless benefits that appeal to different industries. To start with, it fits intricate designs that conventional approaches may struggle to achieve. In addition, the speed of manufacturing is improved, permitting quicker turn-around times and enhanced result. Furthermore, CNC machining is flexible, appropriate for a variety of materials, consisting of steels, plastics, and compounds.

The procedure allows for easy adjustments, allowing fast prototyping and customization without extensive retooling. Therefore, services can react quickly to market demands, making CNC machining a crucial part of contemporary production strategies.

The Value of Accuracy in Milling Processes

Accuracy is important in crushing processes, as it directly affects the accuracy of the final product. The selection of products additionally plays a substantial role, impacting exactly how well the machining procedure meets defined resistance criteria. Comprehending these components is important for attaining excellent lead to CNC machining.

Duty of Accuracy

Achieving high levels of precision is vital in grating processes, as also the tiniest discrepancy can result in significant errors in the end product. Precision in CNC machining straight affects the performance, performance, and durability of the made elements. Exact grating guarantees that dimensions and resistances are fulfilled, which is crucial for components that must fit together perfectly in assembly or run under specific problems. Furthermore, the duty of accuracy includes minimizing waste and revamp, thus boosting total manufacturing performance. Advanced CNC equipments outfitted with sophisticated software program and tooling add to obtaining the needed precision. By focusing on accuracy in milling, manufacturers can ensure top quality results that meet stringent sector standards and client assumptions.

Material Choice Influence

Product option plays a crucial role in the milling procedure, influencing both the quality of the last product and the performance of manufacturing. Various products exhibit distinct properties such as hardness, tensile toughness, and machinability, which straight affect the milling method used. Harder materials might need customized tools and slower feed rates to stop device wear and keep accuracy. Conversely, softer materials can be crushed at greater rates however may do not have resilience. In addition, the choice of product can impact surface area finish and dimensional precision, demanding cautious factor to consider by suppliers. Ultimately, picking the proper material not only enhances item performance yet likewise maximizes the milling process, reducing waste and enhancing general productivity.

Resistance Criteria Value

While the option of products is vital, adherence to resistance requirements is just as important in CNC machining processes. Resistance requirements determine the allowable restrictions of variation in dimensions, ensuring elements fit and operate appropriately. In milling and turning procedures, accurate resistances enhance item top quality, lower waste, and minimize rework. When resistances are precisely preserved, manufacturers can accomplish regular outcomes, which is important for industries such as aerospace, automobile, and clinical tools, where accuracy is vital. Variances from established standards can bring about assembly problems, jeopardized efficiency, and enhanced prices. Understanding and applying correct resistance requirements is fundamental for any CNC machining service looking for to preserve high manufacturing top quality and meet customer specs properly.

Enhancing Efficiency Through Advanced CNC Turning

Advanced CNC turning strategies substantially enhance efficiency in component production by making certain high accuracy in manufacturing. This increased precision not only boosts the total quality of the components generated however additionally adds to minimized production time. As a result, makers can attain better outcome while preserving rigid top quality requirements.

Accuracy in Component Production

CNC turning technology has actually revolutionized precision in component development, allowing makers to accomplish remarkable accuracy and efficiency. Making use of computer-controlled lathes, this innovative procedure carefully forms materials right into complex designs, guaranteeing tight tolerances that satisfy requiring requirements. The automation integral in CNC turning reduces human error, resulting in regularly top notch parts customized to specific requirements. In enhancement, the ability to swiftly change digital designs permits rapid models, enhancing the modification of components without compromising precision. Because of this, sectors ranging from aerospace to vehicle advantage significantly from these developments, as they can generate complex geometries with simplicity. Inevitably, CNC transforming stands as a keystone of modern production, driving precision and reliability in part production.

Reduced Production Time

Key Technologies in CNC Machining

Various key innovations drive the efficiency and precision of CNC machining, enabling suppliers to create complicated components with high precision. Central to these developments are Computer system Aided Design (CAD) and Computer System Helped Manufacturing (WEBCAM) software, which simplify the design-to-production process. CAD enables for elaborate layouts to be produced and controlled digitally, while camera equates these layouts into equipment instructions.

Further enhancing accuracy are multi-axis machining centers, which allow cutting tools to move along multiple axes concurrently, lowering the need for several setups - jig and fixture tooling. In addition, innovations in tooling products and layers have boosted longevity and performance, allowing for better surface area finishes and prolonged device life

Automation innovations, including robotics and intelligent software application, promote real-time surveillance and modifications throughout production, ensuring consistency and quality. Collectively, these modern technologies not only improve manufacturing capacities yet additionally add to the general reliability of CNC machining services.

The Function of Skilled Machinists in Top Quality Manufacturing

Experienced machinists play a necessary function in making sure the top quality and accuracy of CNC machining production. Their knowledge straight impacts the result of producing procedures, as they interpret technological drawings, established up machines, and select ideal tools for each and every project. By having a deep understanding of machining principles, they can make real-time modifications to enhance efficiency and keep tight resistances.

Experienced machinists utilize their analytic capabilities to determine and correct problems during production, stopping defects and guaranteeing that the final products satisfy strict high quality standards (tool and die maker). Their experience with numerous materials and machining techniques allows them to adapt to diverse task demands, improving general effectiveness

On top of that, these experts typically team up with designers and developers, supplying useful understandings that add to the continuous enhancement of production approaches. Eventually, the significance of skilled machinists in CNC machining can tool and die maker not be overstated, as they form the backbone of top quality production procedures.

Minimizing Waste and Optimizing Resources

Reliable CNC machining not just counts on the knowledge of proficient machinists however additionally highlights the significance of minimizing waste and enhancing sources throughout the manufacturing procedure. By employing advanced innovations and exact programs, suppliers can lessen product waste, guaranteeing that every piece of resources is utilized successfully.

Including methods such as nesting, where parts are prepared to take full advantage of product usage, can significantly reduce scrap production. In addition, real-time surveillance of equipment efficiency enables immediate changes, preventing overproduction and resource depletion.

Moreover, carrying out lasting methods, such as recycling metal shavings and using eco-friendly products, adds to both cost savings and environmental obligation.

With these steps, CNC machining solutions can boost productivity while maintaining premium standards, ultimately leading to an extra profitable and lasting procedure. By focusing on resource optimization, organizations can attain better effectiveness and a minimized ecological impact in their production procedures.

Selecting the Right CNC Machining Solution for Your Needs

Just how does one determine the most effective CNC machining service for details project demands? Selecting the proper CNC machining service involves numerous essential considerations. Project requirements, consisting of material dimensions, resistances, and types, need to be clearly specified. This ensures that the selected service can satisfy the technological needs of the task.

Second, reviewing the solution provider's know-how and experience in the appropriate industry can provide understandings into their capacities. Checking out previous projects and client testimonies can further inform the decision.

Third, evaluating the offered technology and machinery is crucial, as sophisticated tools often leads to greater precision and efficiency.

Cost and turnaround time need to be considered to ensure the service aligns with monetary restraints and due dates. By meticulously assessing these aspects, companies can identify the CNC machining service that best fits their unique production demands.

Frequently Asked Concerns

What Products Can Be Made Use Of in CNC Machining?

CNC machining can utilize a variety of materials including steels like aluminum, titanium, and steel, along with plastics such as acrylic and nylon, and composites, supplying convenience for different production applications and industries.

The length of time Does a Typical CNC Machining Task Take?

A common CNC machining job can take anywhere from a few days to several weeks, relying on aspects such as complexity, material kind, style requirements, and production quantity. Timelines vary based upon project requirements and urgency.

Are CNC Machining Solutions Eco Friendly?

CNC machining solutions can be ecologically friendly, especially when using reliable procedures and lasting materials. Waste decrease and energy-efficient machinery add to a reduced ecological influence, making these solutions a feasible choice for eco-conscious manufacturing.

What Industries Commonly Utilize CNC Machining Solutions?

CNC machining services are commonly made use of in numerous sectors, including auto, aerospace, electronic devices, medical tools, and production. These sectors count on accuracy machining for components that need high precision, efficiency, and repeatability in production procedures.

Exactly How Can I Prepare My Styles for CNC Machining?

To prepare styles for CNC machining, one must assure correct file styles, optimize measurements for tolerance, incorporate needed machining attributes, and consider product residential properties. In addition, offering in-depth documentation can boost the production procedure's performance and accuracy.

While the option of materials is essential, adherence to tolerance criteria is similarly essential in CNC machining processes. Competent machinists play a crucial function in ensuring the top quality and precision of CNC machining production. A normal CNC machining task can take anywhere from a few days to a number of weeks, depending on elements such as complexity, material kind, design specifications, and manufacturing quantity. CNC machining solutions can be ecologically friendly, specifically when using sustainable materials and reliable procedures. To prepare designs for CNC machining, one need to assure proper documents styles, enhance measurements for resistance, integrate essential machining features, and consider product residential properties.